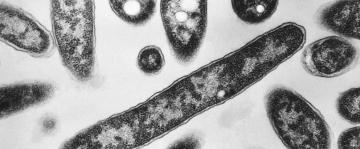

Researchers at CSIR's Advanced Materials and Process Research Institute (AMPRI) in Madhya Pradesh's Bhopal have successfully converted stubble into eco-friendly hybrid wood. This breakthrough might signal some hope for the issue of rampant stubble burning in and around Delhi during winters, which is considered a major factor in the national capital region being covered in thick smog every year.

The Bhopal institute has developed an internationally patented and novel technology for making evergreen hybrid ply and composite wood using parali (stubble) and other industrial waste particulates and fibres as the raw material. Converting the agro-industrial waste into processed wood lowers the consumption of timber, which in turn reduces deforestation. The waste-to-wealth tech wood is 30% cheaper and 20% stronger than conventional particle wood and plywood. Experts feel this can solve north India's long-standing problem of stubble burning by farmers, as it can now be used for making doors, partition panels, roofing sheets, and thermal insulator materials.

Chief scientist at CSIR-AMPRI, Ashokan Pappu, said, "We just need polymer and parali for this. The technology that is ready for commercialisation produces high quality and glossy finish composites that use 60% parali in a polymeric system. This has a great potential for converting parali into cash as well as to generate income for farmers. As compared to particle board and ply board, they are far better. We had interaction with many stakeholders in Punjab and Haryana for recycling parali. We have also filed for patent in India and the US."

The Bhopal-based CSIR lab started working on finding an eco-friendly solution to toxic fly ash generated by thermal power plants in MP's Singrauli district and adjoining areas in 2010. Nearly a decade long research by scientists at AMPRI led to the development of the alternative wood out of fly ash, which was fit for making furniture and decorative items.

Prof Avanish Kumar Srivastava, Director, CSIR-AMPRI said, "This is tested as per BIS norms, it's a waste to wealth technology and will generate a complete circular economy. This wood has been tested on key parameters, including water absorption, mechanical strength, and chemical parameters. It is processed under room temperature, so the requirement of energy is also very minimal. The innovative composite materials have various application potential for civil infrastructure as doors, false ceilings, architectural wall panels, partition and furniture etc. CSIR-AMPRI's technology is a green solution to the parali-burning environmental problem, and contributes to the government's Atmanirbhar Bharat initiative as it creates employment and improves the livelihood of farmers."

The product was showcased at the India International Science Festival in Bhopal, and could be seen in the market in the next two years. The technology has been licensed to a Chhattisgarh based industrial unit, and it is expected that many more industries would be set-up using this technology of CSIR.